How feasible is it to manufacture in the endless vacuum of space? This question beckons us to explore the frontier of space manufacturing and its transformative potential for human industry. As we vault into a new era of technological advancement, manufacturing in space has transitioned from the pages of science fiction into a burgeoning reality. This article delves into how space manufacturing is revolutionizing the very concept of factories in orbit, offering an expansive view of its implications for modern industry and scientific progress.

Table of Contents

Introduction to Space Manufacturing

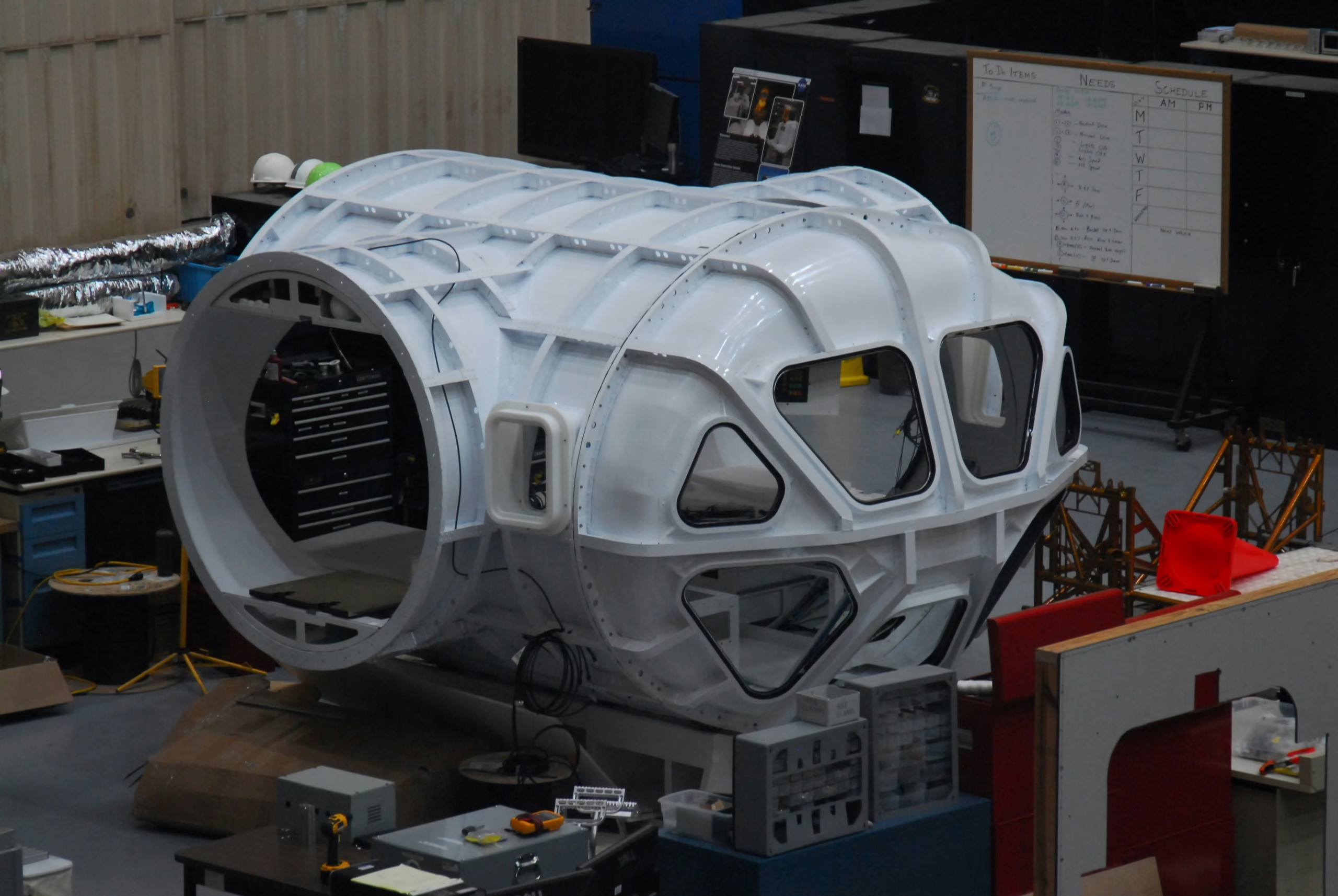

Space manufacturing is not a mere extension of terrestrial factories but rather a paradigm shift, reshaping our understanding and approach to production. In space, we confront unique environments that facilitate manufacturing processes unattainable on Earth. By capitalizing on microgravity, abundant solar energy, and a pristine vacuum, factories in orbit redefine traditional manufacturing capabilities and efficiency.

Origins and Historical Context

The allure of space manufacturing has been compelling scientists and visionaries for decades. The concept can be traced back to the mid-20th century when space exploration was burgeoning, and the possibilities seemed as vast as the cosmos themselves. However, it wasn’t until the past few decades that advancements in technology and significant reductions in launch costs began to transform these ideas into feasible endeavors.

Key Concepts and Advancements

To appreciate space manufacturing, one must grasp the key concepts driving its evolution. These include the distinctive attributes of the space environment, such as microgravity, near-infinite sunlight exposure, and the vacuum of space. These elements create conditions where materials behave differently, allowing for advanced and efficient manufacturing processes.

Microgravity

Microgravity, a hallmark of space, permits novel manufacturing techniques. It enables uniform mixing of materials without sedimentation, resulting in purer and more homogenous products. This is particularly beneficial for producing advanced alloys and pharmaceuticals that require precise molecular arrangements.

Solar Energy

In space, the sun shines perpetually without atmospheric interference, providing a continuous source of solar energy. This offers a sustainable and inexhaustible energy supply, vital for powering space factories and reducing reliance on terrestrial resources.

Vacuum Environment

The vacuum of space eliminates contamination from atmospheric particles, enabling the production of purer materials and enhancing the longevity of manufacturing equipment. This reduction in impurities proves crucial for industries like semiconductor and optical manufacturing, where precision is paramount.

Space Manufacturing Process: A Closer Look

The process of manufacturing in space differs significantly from Earth-bound production lines. By examining each stage, we can better understand how these methodologies redefine efficiency and innovation.

Materials Selection and Preparation

Choosing materials for space manufacturing is critical. These materials must withstand the harsh conditions of space, including extreme temperatures and radiation. Advanced metals and composites, alongside various polymers, are typically chosen for their durability and performance in such environments.

Production Techniques

Space manufacturing employs techniques that leverage the unique conditions of the orbital environment. Processes such as additive manufacturing (3D printing) and in-situ resource utilization (ISRU) play pivotal roles.

Additive Manufacturing

Additive manufacturing, particularly advantageous in space, allows for complex component creation with minimal waste. This method is conducive to building large structures, intricate machinery, and even habitats using materials sourced from space itself, such as lunar or asteroid regolith.

In-situ Resource Utilization

ISRU is the practice of extracting and processing materials found in space, such as water and minerals from asteroids or lunar soil. Using local resources minimizes the need for transporting materials from Earth, drastically cutting costs and increasing self-sufficiency.

Challenges and Solutions

Space manufacturing is not without its obstacles. Engineering solutions to address issues like radiation protection, temperature regulation, and robotic autonomy are essential to ensure the sustainability and safety of orbital manufacturing facilities.

Applications and Benefits

The potential applications of space manufacturing are extensive, spanning various industries and sectors. These applications promise to revolutionize current practices and catalyze further innovation.

Telecommunications and Electronics

Space manufacturing offers the ability to produce purer fiber optics and semiconductor components, resulting in faster, more efficient electronic devices. The absence of gravitational forces reduces defects, enhancing the performance of electronic systems critical for global communications and data transfer.

Medicine and Pharmaceuticals

The pharmaceutical industry is poised to benefit significantly from space manufacturing. Microgravity conditions enable the production of highly pure pharmaceuticals and the growth of superior protein crystals, enhancing drug effectiveness and opening new avenues for medical research.

Aerospace and Construction

Space manufacturing facilitates the in-orbit assembly of large structures such as satellites, space stations, and even solar power arrays. Utilizing materials processed and fabricated in space not only reduces dependency on Earth but also supports the construction of expansive projects otherwise deemed impractical.

Environmental and Economic Impact

The environmental implications of space manufacturing are profound. By shifting certain manufacturing processes to space, we can mitigate pollution and resource depletion on Earth. Additionally, the economic potential is vast, with new industries catalyzing job creation, driving innovation, and enhancing economic growth.

The Future of Factories in Orbit

The frontier of space manufacturing is still unfolding, with ongoing research and development charting its future trajectory. As we forge ahead, continued breakthroughs and collaborative efforts between government space agencies and private companies will shape this burgeoning industry.

Collaboration and Policy Development

International collaboration will be fundamental, fostering innovation through shared resources, expertise, and research. Policy development will also be crucial, ensuring sustainable practices and equitable benefits from space manufacturing endeavors.

Technological Innovations

Future technological innovations promise to further refine space manufacturing capabilities. Advancements in robotics, AI, and material science will enhance the efficiency and scope of orbital factories, enabling even more complex manufacturing processes and products.

Conclusion

The transformation of factories into the realm of space presents an exciting juxtaposition of science and industry. As we continue to explore and expand our manufacturing capabilities beyond Earth’s boundaries, space manufacturing holds the promise of redefining not only how we produce goods but how we envision our place in the universe. By leveraging the unique conditions of orbit, this burgeoning field pioneers cutting-edge production methods, fostering a future enriched with possibility and powered by innovation.

NASA to Transform In-Space Manufacturing with Laser Beam Welding Collaboration